15 May Reorder point: Why is it important for managing inventory? Sage Advice US

Now that we’ve outlined the general advantages of this type of ad, it’s up to you to decide if print media is a suitable platform for you to find new customers and reach your marketing goals. If you deem it beneficial, let’s talk about how you can get the most out of it while saving costs as much as possible since newspaper and magazine ads are not so cheap. By ensuring that there is always the adequate product in your warehouse, you may save money on storage. This will also help you avoid stockouts, overstocking, and lost sales. If you sell 2,400 units in 30 days, your demand average would be 80. Another important feature of reorder https://menxinh.com/how-to-invoice-as-a-freelancer-a-detailed-guide-i/ points is that they are unique to every SKU.

Avoiding stock outs

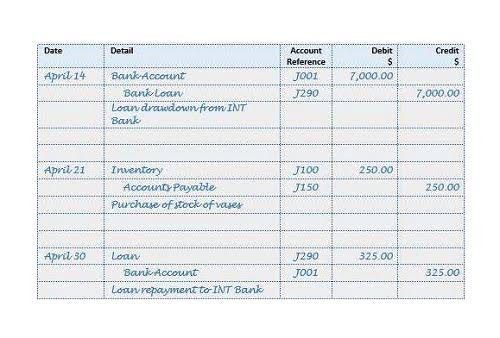

First, you need to find the difference between the expected and actual lead times to get deviance (shown in the above table). Assume that you are a retail shopper and sell soft drinks and snacks. You purchase them from different vendors with different lead times. The company takes, on average, five days to produce one doll, but occasionally it How to Run Payroll for Restaurants takes ten days to make one doll because of the delay in the production process. It’s the level of stock that triggers a reorder to prevent stockouts.

Calculating Reorder Point With Easyship

- If a business underestimates this duration, it may run out of product before the new order arrives.

- The math is easy enough for any merchant to be their own reorder point calculator.

- The total number of units sold during that time is then divided by the number of days in the period.

- That is, they are triggered by stock dropping below the reorder point.

- So does this mean investing in advertisements in newspapers and magazines is a waste of resources?

- These systems automate manual processes that are prone to human error or oversight.

Sage makes no representations or warranties of any kind, express or implied, about the completeness or accuracy of this article and related content. Remember, the key to successful ROP management is continuous monitoring and adjustment in line with your business dynamics. From preventing stock outs to optimizing storage space, you’ll learn about the tangible impacts of ROP on your business’s efficiency and profitability. This long-term view is vital to account for seasonal variations and other fluctuating factors that can affect your sales volume. It’s the secret ingredient to ensuring you always have just the right amount of stock at the right time without overfilling your storeroom, or worse, running out. While implementing a reorder point strategy may not address the whole puzzle, it provides a more exact basis for your stock replenishment schedule.

How to Calculate the Reorder Point

However, when used solely to control the supply plan, the company performs reorder point planning instead of forecast-based planning. MRP/DRP and APS (heuristic, allocation, cost optimization, inventory optimization) methods are forecast-based planning. The accuracy of Reorder Point calculations depends heavily on the quality of the underlying data. Common challenges include incomplete sales data, variability in lead times, discrepancies in inventory counts, and the relevance of historical data, particularly in rapidly changing markets. The retail sector faces unique challenges in ROP management due to its fast-paced nature, changing consumer preferences, and seasonal fluctuations, making effective inventory management critical.

- If you run out of stock, you’ll be unable to make sales until new inventory arrives.

- Optimize your eCommerce supply chain with practical insights and solutions.

- And you avoid overstocking inventory and storing that stock at the cost over a period of time.

- Safety stock is like your backup plan for those unexpected moments—think of sudden rushes in demand or hiccups in your supply chain.

- I dont think any ERP is covering all these aspects in 100 percent.

This is necessary because any component requiring more than a week or two of manufacture could well be in short supply at the beginning of the next quarter if not what does rop mean in business planned for. In this way, reorder point planning can be used for deployment, which would mean removing them from the product location combinations from the used planning procedure. This is simple to do with most supply planning applications I have used. Until now, we have discussed reorder point planning for the initial supply plan, which generates the purchase requisitions and the planned production orders. However, replenishment/reorder parameters are available at all the locations in a supply network.

- Typically, when you don’t have safety stock, your reorder level and the frequency of your orders tend to be higher.

- Implementing these strategies will position your business for greater success and sustainability.

- You can even adjust how far back the system looks to calculate your sales velocity, allowing you to adjust for any potential seasonality or outlier sales.

- If you’ve ever dealt with the hassle of running out of stock or the headache of having too much, you understand the importance of nailing inventory management.

- Determining the re-order point involves considering various factors such as lead time, demand variability, and desired service level.

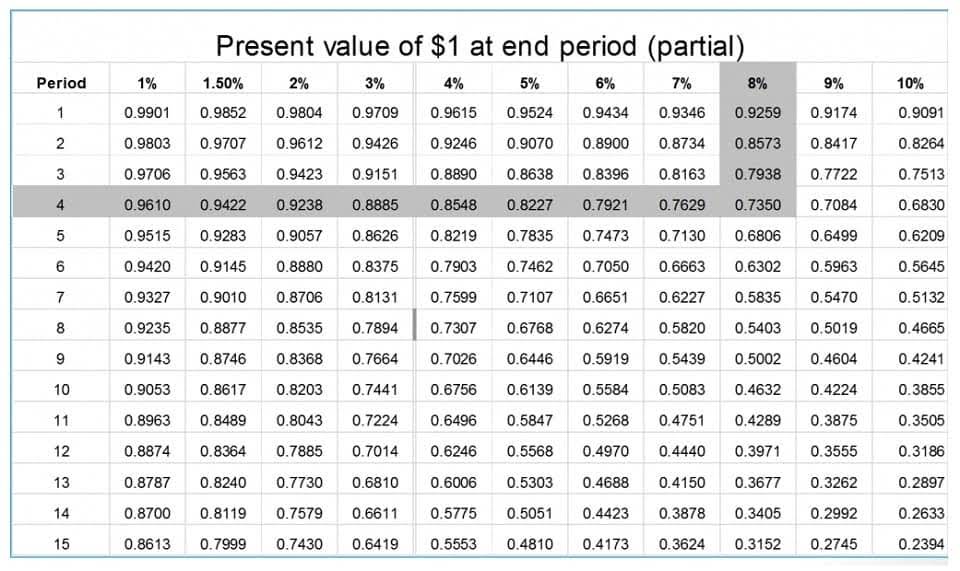

Reorder quantity, on the other hand, is the amount of stock that should be ordered to replenish the inventory. All we need to do now is add your lead time demand number to your safety stock number. Your maximum daily orders are the highest number of a certain item you can reasonably expect to sell in a day. Multiply this number by the maximum number of days it could take a supplier to deliver new inventory to you.

- Compare discounted rates from USPS, UPS, FedEx, and 250+ global couriers at a glance.

- Additionally, sustainability considerations may influence Reorder Point strategies to optimise not just for cost and service levels, but also for environmental impact.

- This is because for slow moving items it is possible that there will be no additional demand before the newly ordered item(s) arrive in stock.

- A business might exclude a major one-time sale from the calculation to avoid skewing the daily average.

- This type of simple “requirements planning” technique has been used for many years.

Each inventory item can have distinct demand patterns, lead times, and levels of importance. It is often more effective to customize reorder point strategies to align with the unique characteristics of each product or item in your inventory. To calculate your demand average, choose a time period, determine how much product you sell in that time period, add up your units, and divide by the number of days in the time period. Demand forecasting strategy is an advance way to calculate future demand of your products as well. To maintain an accurate reorder point, check the underlying metrics — average daily sales/usage and average lead time — at least once per quarter. If you have a high season and low season, or seasonal bad weather that slows down deliveries, factor this in.